Washer family

Washers are produced in a wide variety of designs and within those individual designs are a range of materials, dimensional variations and finishes.

Washers and the origin of the word are unknown; the first recorded use of the word was in 1346, the first time its definition was recorded was in 1611.

While every assembly and fastening process requires a variety of components for successful operation, washers are a vital component. Washers can be used under the head of the fastener, bolt, screw, or under the nut or a combination. Washers are designed to perform functions in particular applications; these may be locking, load spreading, protection, decorative, tension indicating, sealing, or a combination of these roles. Washers are also important for preventing galvanic corrosion, particularly by insulating steel screws from aluminium surfaces.

Links:

Flat washers: Metric DIN British Standard American ANSI Inch British Standard American ASME

Fender Penny Repair washer Hardened washer Neoprene washer Fibre washer

Locking washers: Spring Coiled Split Lock washer Contact washer Wedge Locking washer Serrated Safety washer

Tooth lock washers: Internal Tooth External Tooth Countersunk Tooth Internal-External Tooth combined

Curved/Disc washers: Disc spring washer Belleville washer Cylindrically Curved washer Wave washer

Construction washers: Structural washer Load Indicating Coronet washer

Screw Cup finishing washer Square washers Square Hole washer Taper washer

Tab washer Countersunk washer Spherical seating washer Shoulder washer SEMS washer

.

.

.

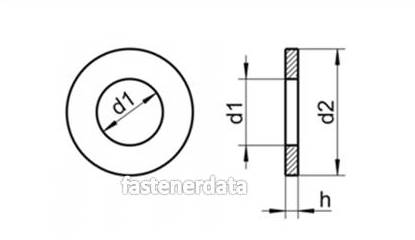

Flat washers

Flat washer’s prime function is to spread the bearing face pressure, clamp load, under a bolt or nut over a larger surface area, preventing damage.

Washers are primarily manufactured to standard specifications in various sizes, materials and shapes. Flat washers are thin, flat and circular general-purpose washers with a centrally located hole. Internal and external shapes are normally round. The hole or outer diameter can be non-symmetrical depending on the function of the washer. Flat washer sizes are designated by the shank diameter of the fastener in which they form part of the assembly.

Din Standard flat washers are the norm for Europe and Din 125A is the most popular product, it is available in a range of materials and sizes. The 11 different standards DIN range is shown on fastenerdata with a size comparison chart.

Metric flat washers to the British Standard BS4320 range from form 'A' through seven forms to 'G' and are popular because they give size options that the German Din standards do not. BS4320 Form A flat washers are virtually identical to Din125A.

USA metric flat washers are to ANSI B18.22M the full range of narrow, regular and wide is shown on fastenerdata with a size comparison chart.

Inch UK flat washers to BS3410 table one through to table nine is shown on fastenerdata with a full range size comparison chart.

USA Inch flat washers are to ASME B18.21.1 the five different types are shown on fastenerdata with a size comparison chart.

Fender Washers or Penny washers as they are called in the UK have a larger outside diameter compared to traditional flat washers. The name, “Fender,” is derived from their use in the USA automotive industry where they are used to mount fenders (bumpers) Mud wing washers and penny washers where the outside diameter is UK old penny size or bigger. Fender/Penny washers distribute a load evenly across a larger surface area. Flat washers whose outer diameters measure more than three times the inner diameter are commonly referred to as fender washers also DIN9021 washers. The full range is shown on fastenerdata with sizes.

Hardened washers

Inch USA and UK Hardened Flat washers are used under bolt heads or nuts to increase the bearing area and to offer hardness so that the nut or bolt can be rotated without distortion of the bearing surface. Hardened Flat washers are used to give tightness to a joint, to prevent leakage, and especially to distribute pressure under the head of a nut or bolt. Globally sold F436 and F436M American specification hardened washer and DIN 6916 and DIN 6340 washers are commercial specification washers for the construction market. In addition, there is a range of hardened washers to both BS EN14399-6/9 and 15048 covering construction steelwork.

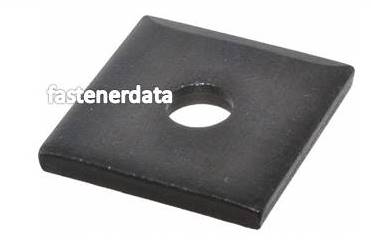

Construction square plate washers should be used instead of round washer for timber building and concrete floor applications; they are used with all fasteners for larger load distribution and bolting through a wall or timber.

Used in the woodworking and fencing industry in combination with coach bolts and coach screws that have a square section under the bolt head; the washer locates on the square under the bolt head.

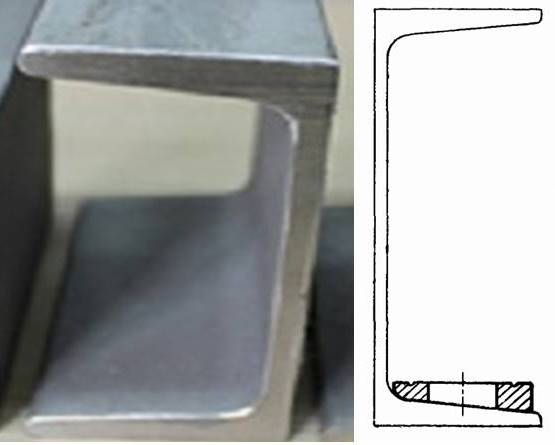

Taper Washer

Taper Washer

Taper washers are designed to be used on channel sections, underneath nuts with tapered flanges to enable the bolt assembly to fit square when tightened.

Coiled spring washers provide a vibration resistant function, they consist of ring split at one point and bent into a helical shape, this causes the washer to exert a spring force between the fastener's head and the bearing face which maintains the washer hard against the face and the bolt thread hard against the nut or threaded hole, creating more friction and resistance to rotation. Spring washers are a left-hand helix and allow the thread to be tightened in a right hand, clockwise direction. When a left-hand turning motion is applied, the raised edge bites into the underside of the bolt or nut and the part that it is bolted to, resisting turning. Spring washers are ineffective on left-hand threads and on a hardened surface, they should not be used in conjunction with a flat washer under the spring washer, as this isolates the spring washer from biting into the component that will resist turning. Spring washers are produced to various standards that denote the thickness and section size, normally square or rectangle section. Popular spring washers are single coil but can also be supplied as a double coil washer.

Washers with surface ribbed serrations on either one or both flat surfaces designed to bite into the joined material or the bolt or nut to either improve the electrical contact or a locking action.

Serrated Safety Locking washer

Serrated Safety Locking washer

Safety washers are a cross between a disc spring with a trapezoidal cross-section and serrations on both sides of the washer. Due to the safety washers conical form, optimal traction is achieved at the highest positive locking due to the helical gearing. When flattening of the safety washer occurs with tightening of the screw, serrations on both sides bite into the mating faces preventing loosening of the screw due to vibration. In addition, the disc spring profile assists in retaining the required screw tension.

Washers designed to be used as a mating pair they have a central wedge action. Their locking abilities are considerable and far superior to spring or toothed washers. Wedge locking paired washer systems delivers anti-vibration security for the most demanding of bolted joint applications. Even under extremes of vibration or dynamic loads, wedge lock washers provide Maximum reliability. When the bolt is tightened, the external radial teeth of the wedge lock washers embed themselves in an interlocking fashion with the mating surface. If the securing system is subject to dynamic stress, movement is only possible between the internal washer surfaces. This results in an increase in the preload force.

Nord-lock Heico Disc-lock Grower

Tooth locking washers have teeth that are twisted to grip and extend radially inward to bite into the bearing surface. This type of washer is especially effective as a lock washer when used with a soft substrate, such as aluminium or plastic. Tooth washers can resist rotation more than a plain washer on hard surfaces; the tension between the washer and the surface is applied over a much smaller area by the teeth. The internal style has the serrations along the inner edge of the washer, which makes them more aesthetically pleasing.

Tooth lock washers are also used for ground bonding where a metal lug or object must be electrically bonded to a surface. The teeth of the washer cut through surface oxides, paints or other finishes and provide a conductive path. In these applications the washer is not placed under the head of the screw or under the nut, it is placed between the surfaces to be bonded. In such applications, the tooth washer does not provide any anti-rotation locking features.

Shakeproof Product Fan disc Product

Tooth locking washers with teeth that are twisted to grip and extend radially outwards (external) to bite into the bearing surface. This type of washer is especially effective as a lock washer when used with a soft substrate, such as aluminium or plastic, and resist rotation more than a plain washer on hard surfaces. The external style has the serrations around the outer edge, which provides better holding power, because of the greater circumference area.

Shakeproof Product Fan disc Product

Countersunk toothed washers are designed to be used with flat-head (USA) countersunk screws in a countersunk hole. The teeth grip into the countersink and screw assisting locking.

The combination style has teeth about both edges, with teeth that are twisted to grip and extend radially inward and outward for maximum holding power, the best of both the internal and external tooth locking.

Hardened steel structural washers are used in combination with structural bolts in heavy construction applications. The washer reduces galling between the tightened surfaces and spreads the load; the three external tabs identify it as a structural washer.

Coronet load indicating washers are used in the structural industry to provide evidence that the required tension has been achieved. The raised protrusions will crush in relation to the load applied, providing a permanent observation that the required tension has been achieved, this can be measured with a gauge. They form part of high strength friction grip EN BS EN 14399 assemblies.

Disc spring washers to DIN2093 are also known as spring washers or disc springs, feature dished washers that compress with a proportionate resistance to return to their pre-deflected shape. Disc spring washers are employed in applications where assemblies need a part to take up the slack, maintain assembly tension, compensate for expansion or contraction in materials, or to absorb intermittent shock loads and provide a controlled reaction under dynamic loads. Disc Springs are small and generally weigh less than alternative spring solutions.

Belleville washers are often described as conical or spherical spring washers because they have the form of a truncated cone or truncated sphere. These washers have the smallest deflection ranges and the highest load capacity. The load and deflection capability is dependent on height to thickness ratio. Belleville washers are common in thermal expansion applications and are used to solve spring problems of high loads, limited space and small deflections. Similar to disc springs Belleville washers are the original concept. They can be used in stacks or series to increase the axial load or to increase the possible deflection length.

Cylindrically curved washers, also known as “Crescent,” “Bowed” or “Curved” washers, have the most uniform spring constant over the widest deflection range of any of the spring washer types. Their spring rate is approximately linear throughout the entire deflection range. These washers are ideal for lighter loads ranging from a few ounces to about 100 pounds and are ideal for flexible, load-cycling applications. Generally confined to light applications where only very light pressure is required

Similar to a Belleville and disc springs except the washer is curved in only one direction, therefore there are only four points of contact.

Wave washers, sometimes referred to as Wave Springs have a multitude of waves in the axial direction, generally three but up to six. By increasing the number of waves, the thickness can be reduced for a given load, by decreasing the amount of deflection and increasing the radial stress. Wave uniformity is important because the load/deflection rate will not start until all waves are evenly loaded. Wave washers are ideal for obtaining loads when the load is static or the working range is small and the amount of axial space is limited. These washers are typically used as cushions or spacers to take up variations where some pressure is required on a free element in assembled parts. They can be used in place of spring washers where surface damage is to be avoided. Wave washers, of comparable size, do not produce as much force as disc springs or Belleville washers.

Tab washers are a type of lock washer, round in shape and often manufactured with a single tab or multiple tabs and notches that can be formed to shape around bolts and nuts. These washers are ideal for use in harsh environments, effectively locking a part into place in applications requiring extreme heat conditions or heavy vibrations.

Neoprene washers are excellent in resisting ozone, many chemicals, and oxidation as well as performing in a range of temperatures and are used in numerous weathering sealing applications. Neoprene washers perform well when used in applications where oils are present as well in various construction applications where sealing with a high tensile strength and low compression set material is of principal importance. Neoprene can be bonded to Steel, Aluminium and stainless steel washers.

Fibre washers are a fibre material washer available in red fibre, black fibre and grey fibre. They are sealing washers used for liquid and gas sealing.

Used under a countersunk wood screw where a decorative or appealing finish is required. They are produced by light pressing steel, stainless steel or brass and then either nickel or chrome plated.

Countersunk washers are more substantial than screw cup washers, like screw cups they have a countersink that captures the head of the fastener. They are available in several shapes including 90 degree countersunk, angle countersunk, flanged and un-flanged.

Seating washers or spherical seat washers as they are often called are dish shaped washers in either a male with conical base or female with a concave base. As a pair, these seating washers come together to be flat. Seating dished design is Ideal for locating two elements into a fixture, the seat washer gives you a visual indication the dowel or screw is accurately located.

Shoulder washers, also known as Step washers and have an appearance of a low-crowned top hat and an integral cylindrical sleeve bush. The sleeve is designed to mate with a cutout and segregates the fastener from the material it is secured to. These washers are used primarily in the electronic equipment industry as insulators and made of non-conductive materials.

SEMS washer

SEMS washer

Encapsulated of the washer assembled on a screw or bolt is called a SEMS unit. Pre-assembled SEMS screws are also called combi screws, combine a screw with one or more free spinning captive washers. There are literally hundreds of SEMS screw combinations to choose from, some of the most popular SEMS screw combinations, including external shake proof, internal shake proof, and every configuration of flat and spring washers.

Sometimes call a K-lock nut, keps nuts have an integral free to rotate external shakeproof toothed washer captured on the nut.

The combi nut is similar to the Keps in that an integral free spinning flat washer is captive to the nut making assembly much easier and faster.

Washer Materials

Any type of material that can be stamped, pressed or cut can be made into a flat washer. Washers are manufactured in a broad range of metallic and non-metallic materials, including low and high carbon steels, stainless steel and steel alloys, copper-based materials, beryllium copper, phosphor bronze, titanium, aluminium, fibre, mica, Mylar, rubber, nylon, PTFE and phenolic.

Washer material is important because some applications require a specific material to ensure the washer endures environmental conditions. For example, if a washer goes through cyclic loading, strength and fatigue resistance are important design criteria and require the use of high-alloyed steels or spring steels in the case of spring and disc washers. Non-metallic materials are used when washers are subjected to lighter loads or soft surfaces that could be damaged by a metallic washer.

Washers

flat washers, Locking washers