History of the screw

Screw Thread

HISTORY of the: Nail Rivet Drives Fasteners Pre-1800 Fasteners Post-1800

Screw Thread History

Screw thread history can be traced back to around 400 BC, the screw was described by the Greek mathematician Archytas of Tarentum (428–350 BC) the founder of mechanics and considered a contemporary of Plato; Describing is not the same as inventing and I am sure that this page may have to be revised at some point.

Archimedes less than 100 years later (287 BC–212 BC) we believe further developed the screw principle and used it to construct devices to raise water. There are historical signs that the water screw may have originated in Egypt well before the time of Archimedes. It was constructed from wood and was used to irrigate land and remove bilge water from ships.

Screw Threads

By the first century 100BC, wooden screws were commonly used throughout the Mediterranean in screw presses for pressing olives to produce olive oil and grapes for Juice in winemaking.

Metal screws used as fasteners were rare in Europe before the 15th century and produced in single figures for specific jobs.

Handheld screwdrivers called turnscrews in English, or in their original French name, tournevis, have existed since the 16th century, becoming more widespread 200 years later, once threaded fasteners themselves had become standardised.

Moving forward to the 15th century, Johann Gutenberg used screws in the fastenings on his printing presses. The tendency to use screws gained momentum with their use being extended to items such as clocks and armour.

.

Screw Thread Production

Screw threads for fasteners were made by hand but soon, due to a significant increase in demand, it was necessary to speed up the production process.

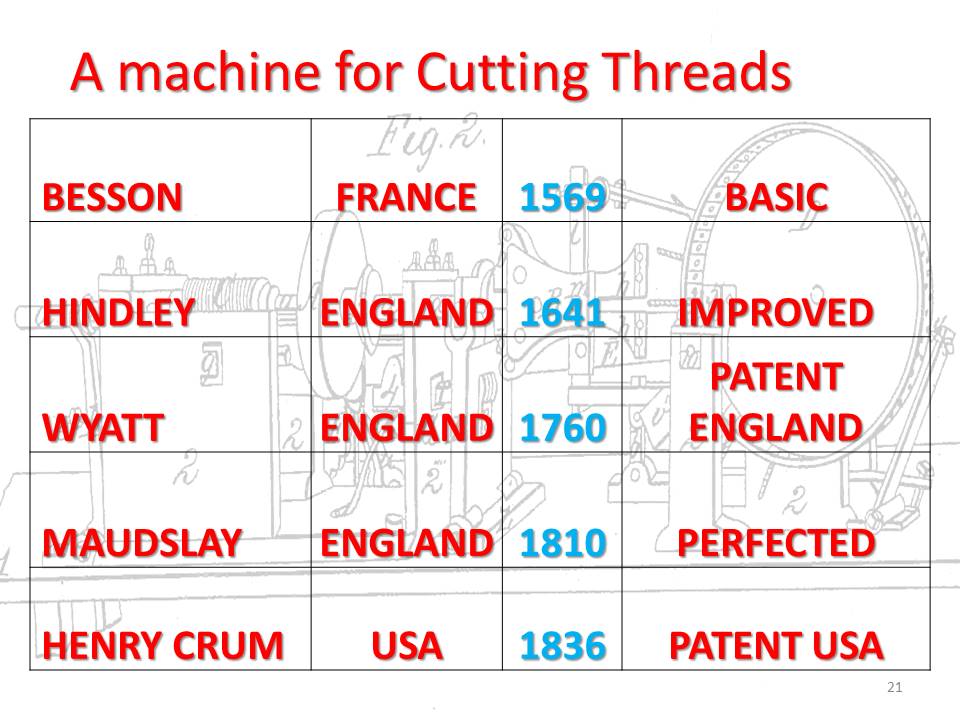

The first machine for making screw threads was made by Besson in France in 1568, who later introduced a screw-cutting plate to be used on lathes.

In 1641 the English firm, Hindley of York, improved this device and it became widely used.

The brothers Job and William Wyatt of Staffordshire, UK, in 1760 created the first patent on a screw machine. It used a leadscrew to guide the cutter to produce the desired pitch.

Sixteen years later in 1776, the Wyatt brothers were producing wood screws in their own factory, by the 1780s they were producing 16,000 screws a day with only 30 employees the kind of industrial productivity and output that would historically be called modern industry but was revolutionary at the time.

Meanwhile, English instrument maker Jesse Ramsden was working on the toolmaking and instrument marking the end of the screw-cutting problem, and in 1777 he invented the first satisfactory screw-cutting lathe.

The British engineer Henry Maudslay gained fame by popularising lathes with his screw-cutting lathes of 1797 and 1800, containing a leadscrew, slide rest, and changing gear train for industrial machining. He converged the paths of the Wyatt's and Ramsden and did for machine screws what had been done for wood screws. His firm would remain a leader in machine tools for many years afterwards.

Screw Thread Developments

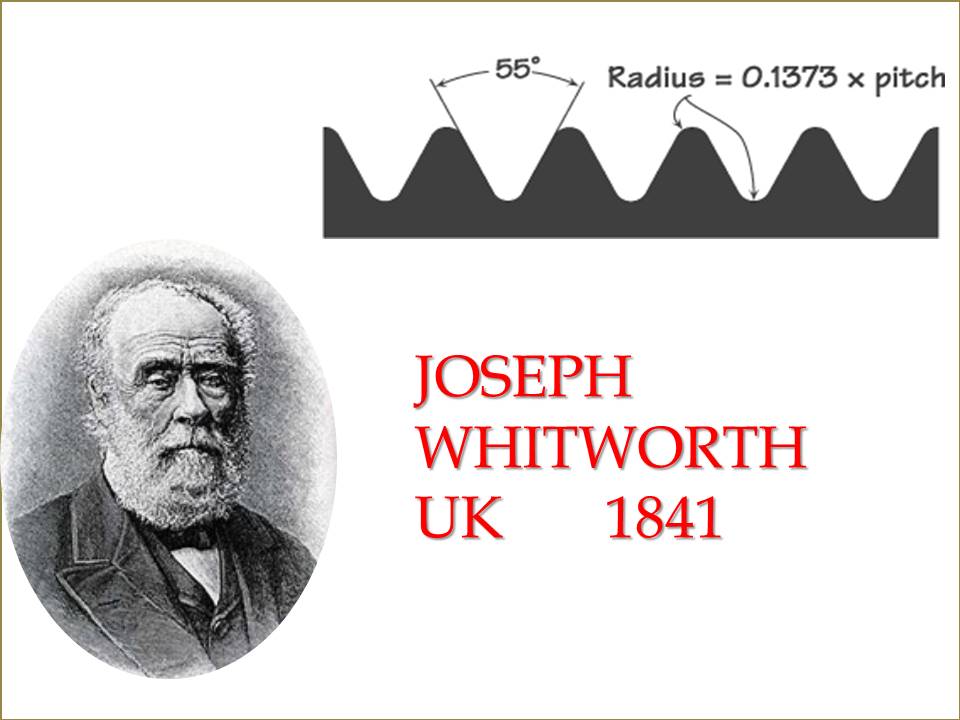

Developments in screw cutting caused great increase in the use of threaded fasteners, no thread standards existed at the start of the 19th century, each company manufactured its own threads, there was a huge range of different sized screw threads on the market, causing problems for machinery manufacturers during assembly if external parts had to be used and with the supply of replacement parts later on. The huge demand for uniform screws for tracks and railway construction resulted in the adoption of national standards and the standardisation of screws and nuts became a necessity. Companies with special machines and tool pieces for producing threads were established and the screw became a cheap, mass-produced article. Joseph Whitworth introduced core and external diameters from a practical standpoint using British inch imperial sizes. The system proved to be so good that it remains virtually unchanged and is still used up to this day.

Joseph Whitworth

It wasn’t until 1841 that Joseph Whitworth managed to find a solution. After years of research collecting sample screws from many British workshops, he suggested standardising the size of the screw threads in Britain so that, for example, someone could make a bolt in England and someone in Glasgow could make the nut and they would both fit together. His proposal was that the angle of the thread flanks was standardised at 55 degrees, and the number of threads per inch, should be defined for various diameters.

While this issue was being addressed in Britain, the Americans were trying to do likewise and initially started using the Whitworth thread.

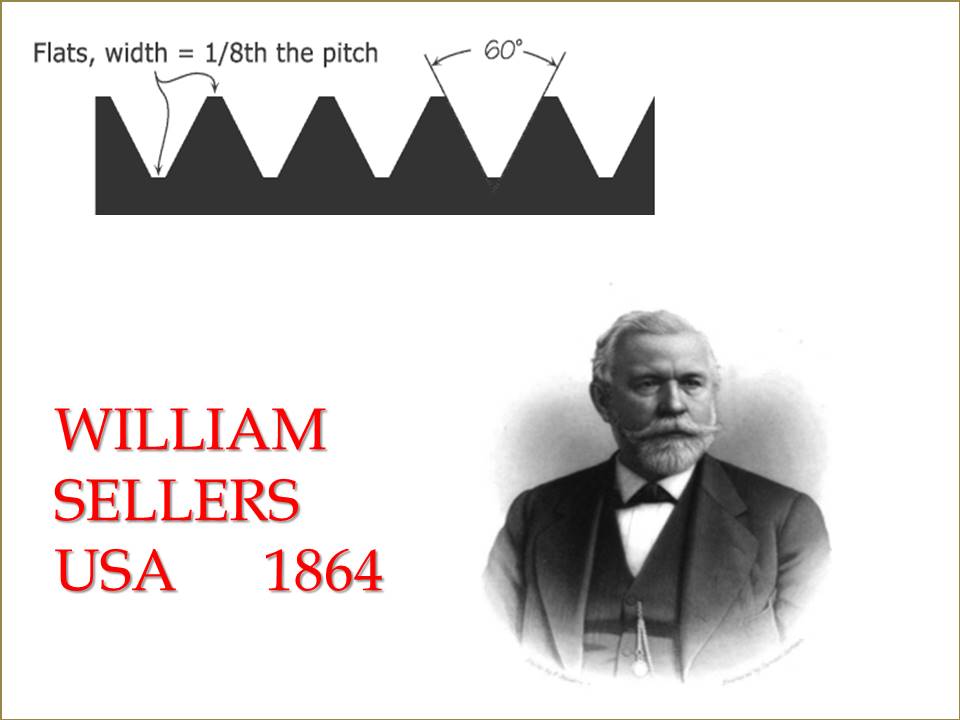

William Sellers

In 1864, William Sellers proposed a 60-degree thread form and various thread pitches for different diameters. This developed into the American Standard Coarse Series and the Fine Series. One advantage the Americans had over the British was that their thread form had flat roots and crests. This made it easier to manufacture than the Whitworth standard, which had rounded roots and crests. It was found, however, that the Whitworth thread performed better in dynamic applications and the rounded root of the Whitworth thread improved fatigue performance.

Screw Thread Development

During the first World War 1914-1918 the lack of consistency between screw threads in different countries became an obstacle to the war effort; during the Second World War, it became an even bigger problem for the Allied forces. In 1948, Britain, the USA and Canada agreed on the Unified thread as the standard for all countries that used inch imperial measurements. This was a combination of the best of the Whitworth thread form the rounded root to improve fatigue performance and the Sellers thread 60-degree flank angle and flat crests.

Metric Screw Threads

Metric thread development started in Switzerland in 1876 with a metric thread with an angle of 47.5 degrees developed for the clock screw market by professor Thury. This was followed in Germany in 1894 by Leopold Loewenherz who designed a thread with a flank angle of 53 degrees 8 minutes. A metric standard thread evolved from these Swiss and German threads that were agreed but not formalised by the American, British and French in 1919. Metric threads are based upon a 60-degree flank angle with flat crests and rounded roots. It was not until 1947 with the re-founding of the International Standards Organisation (ISO) that further development took place eventually leading to the promotion of the ISO standard metric thread in 1960.

Future of Screw Threads

With continental Europe and slowly the rest of the world turning to ISO metric screw threads both the UK and the USA have moved in the same direction. The ISO metric screw thread is now the standard that has been adopted worldwide and is slowly displacing all former standards. Industrial globalization produces market pressure in favour of slowly phasing out minority standards with the USA and UK automotive industry having very few parts for new cars based on Inch sizes. I am sure that old type thread forms will still be required to repair classic cars and other forms of equipment that is not readily replaced.